Integration and Compliance Testing

Testing is critical.

Coordination and planning is key to getting a product to market quickly and with proper testing to meet compliance and de-risk your product launch. We are here to help.

Why work with DE Design Works? Because we have great PCB layout artists, grounding knowledge, and experience in designing products to meet certification that drastically lowers risk. Our internal lab can pre-test for conditions that will save you time and money in the long run.

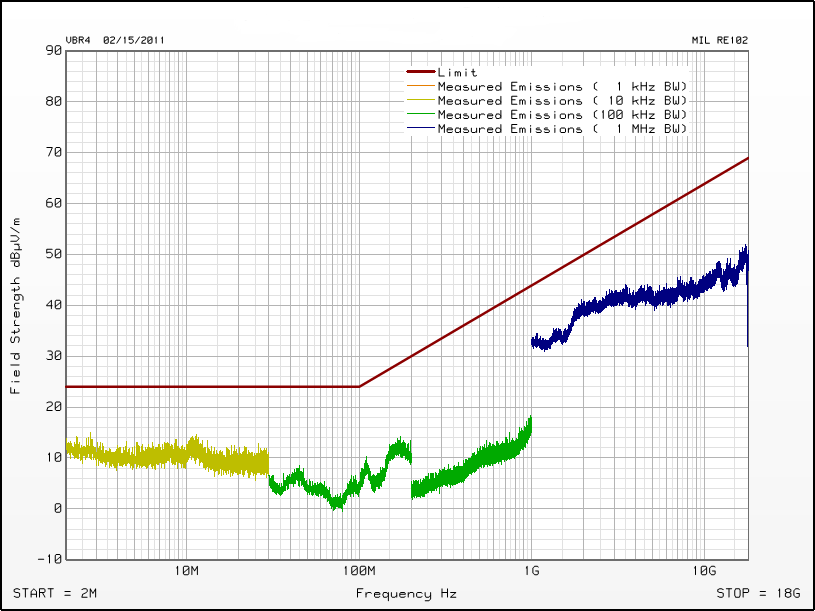

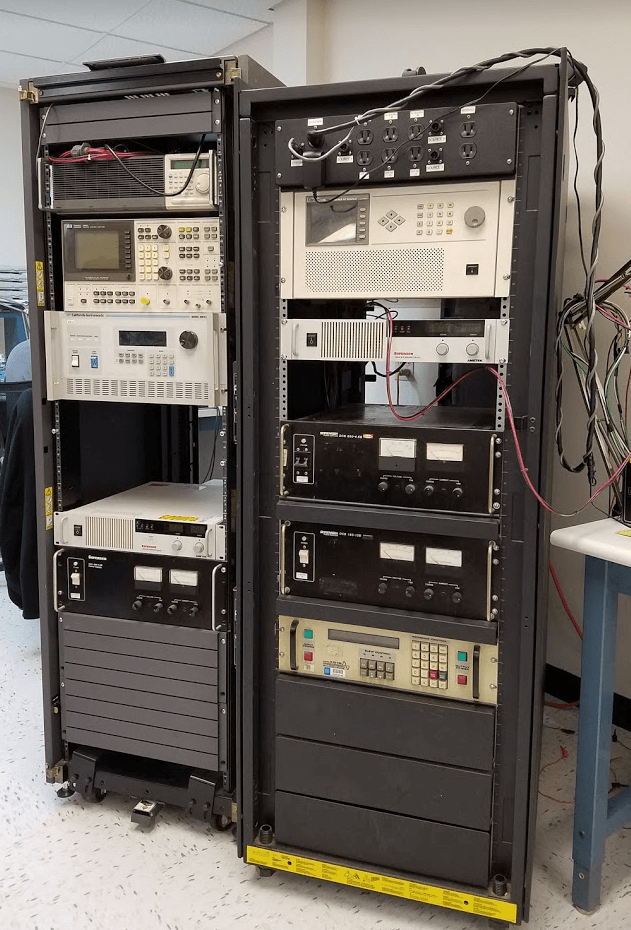

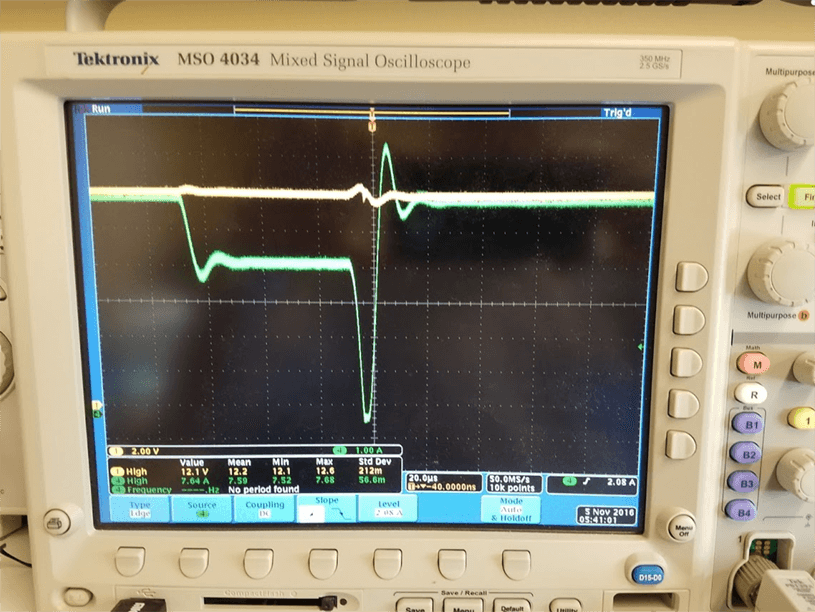

Our lab has complete AC and DC power testing capability for nano-Amp low power analysis through 3,000 Watts. We can inject power fluctuations, noise conditions, and brown out conditions to simulate noise concerns in the field. We have environmental chambers as well as shake and vibration testing capabilities. We can scan your system for EMI radiated emissions issues and evaluate your designs with recommendations from improvement as well as support ETL, CE, CSA, UL, MIL-STD-461 RE102, etc

Certification Support for Design to Production Transition:

- IEC60601 qualification support for pre-FDA compliance testing

- MIL-STD-8100

- MIL-STD-461

- Radiated Emissions Testing Support - EMC/RFI

- ESD testing

- CE and CSA testing and documentation

- Temperature Cycling of electrical sub assemblies

- Life Cycle Testing

- ETL listing qualification support

- UL listing qualification support

- FCC testing support

- Vibration Testing for electrical sub-assemblies

- Motor control load testing up to 3kW including transient loads, peak and holding torque, FOC sensor less, Speed and Position testing

- Power transient testing - DC and AC power, single phase and 3 phase up to 2kHz including harmonic noise injection and brown out testing and data reports

Production Scale Up Support:

- Custom automated functional tester design for volume manufacturing

- ICT design support

Call Us Today For An Assessment!