Motion Control and Robotics Applications

DE Design Works programmers are experts in integrating motor control hardware and supporting your applications for advanced motion control needs.

Motion control applications we have experience supporting the development of:

- Automated Guided Vehicle (AGV) Applications

- Agricultural robotic applications

- All Electric off road vehicle cutting systems and traction control integration

- Medical motor tables

- After market automotive fuel pump systems

- Waste Water treatment systems

- HVAC damper motor drivers

- HVAC split phase and BLDC for constant CFM air flow applications

- Fitness Industry ACI 3kW tread mill drive

- Furniture Industry Linear Actuators and Massage Motors

Target Systems Experience:

- Linux BSP and Bare Metal Embedded C Programming

- dsPIC FOC and advanced motor control applications

- SMART and ARM Core for Atmel, NXP, ST targets

- TI InstaSpin

- Advanced custom absolute and relative encoder designs

Our team of advanced motor control and motion control experts is here to help.

Algorithms:

- FOC, SVPWM,

- Sensorless Park Clark Transforms, Slide Mode Observer

- SMART for ARM

- Feed Forward

- Position tracking

- Multi-axis coordinated motion

- EtherCAT

- CAN bus

- A2B

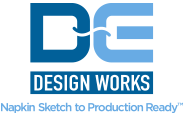

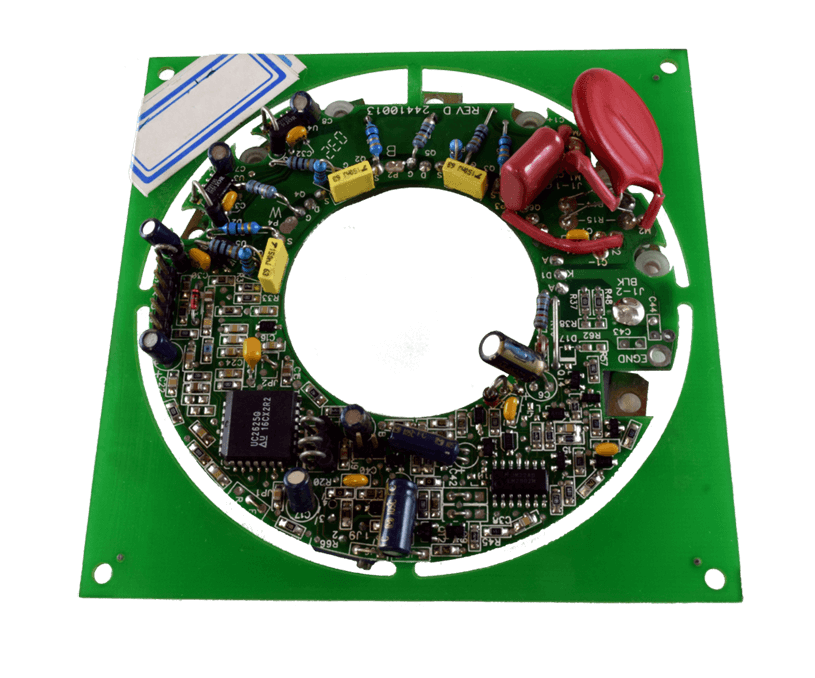

Hardware and Prototyping:

- Custom test stand and PC application development

- Quick Turn Prototypes

- Custom Hardware Design - Power, Magnetics

- Dynamometer load testing, power transient testing, EMC/RFI compliance support, ESD testing, FMEA Risk Analysis

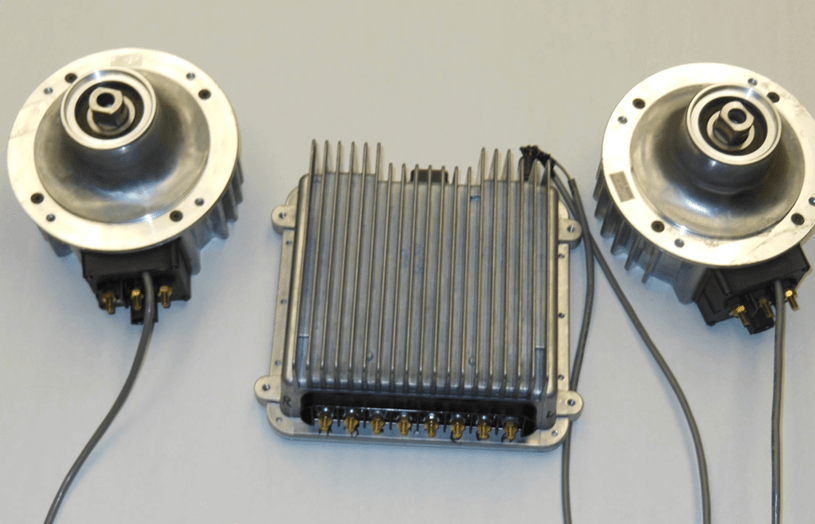

To us motion control firmware for applications is on top of a solid motor control hardware and firmware foundation. We offer complete support of the vertical engineering of advanced motor control algorithm support and development and have experience using NXP, TI, Microchip, and ST platforms including advanced motor control software and hardware integration of Field Oriented Control (FOC) algorithms. This advanced level of motor control is in applications that require high efficiency, fast torque and speed or position control. These implementations offer advanced performance and control.

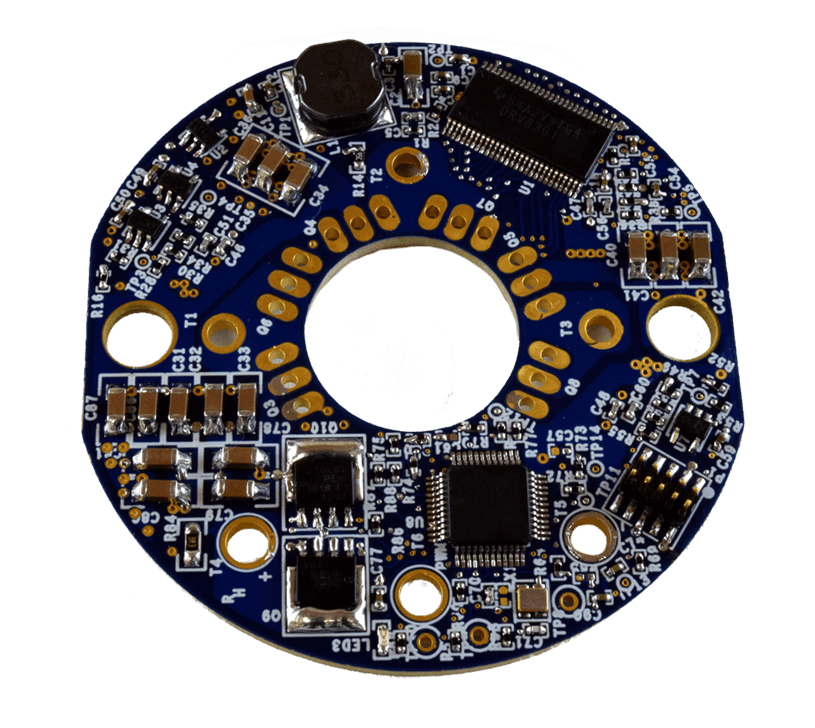

- Custom AC Induction (ACI) Controller Design

- Custom Brushless DC (BLDC) Controller Design

- Custom Permanent Magnet Synchronous (PMSM) Controller Design

- Custom Brush Drive (Full & Half Bridge) Controller Design

- Custom Reluctance Controller Design

- Custom Stepper Controller Design

- Custom Field Oriented Control (FOC) Software Implementation

- Sensorless FOC Software Expert Staff

- Space Vector PWM (SVPWM/6 state) Drive Control Experience

- Volts per Hertz (VPF/FPHz) Product Development

- Sine PWM drive algorithms

- Power Efficiency Improvement Expert

- EMI/EMC Reduction (conducted, susceptibility, radiated emissions)

- pre-Certification for MIL UL CE CSA ISO SAE standards

- Servo Control Design Expert