Electronics engineers must navigate complex product certifications, especially in industries where compliance is crucial. Underwriter Laboratories (UL) certifications are particularly significant in affirming product safety and performance. Achieving and maintaining these certifications requires a collaborative effort among engineers to ensure adherence to an array of interconnected standards. A UL certification demonstrates a manufacturer's commitment to delivering high-quality, reliable electronics, mitigating risks, and positioning products favorably in the market.

As an engineer, it is crucial to differentiate between terms such as "UL Certified", “UL Tested” and "UL Listed" because it can impact design decisions. Safety remains the primary concern as electronic designs become more complex. Various challenges can arise, such as the possibility of overheating or component failures, among others. Aligning with UL and similar standards is not only a matter of compliance but also guarantees that your products are safe and dependable.

Dedication to a well-planned certification strategy is crucial for success.

- Enhanced Product Safety and Reliability: UL's guidelines are a roadmap to designs that function safely and as envisioned.

- Credibility and Trustworthiness: A UL-compliant product resonates with market trust, boosting your brand and product reputation.

- Competitive Edge: Having certifications can provide your product with a competitive edge in a crowded market. It can differentiate your product from others and adds credibility to your brand.

- Mitigated Risks: Safety standards help shield against potential legal and financial pitfalls linked to product issues.

- Efficient Product Development: By starting the design process with certification standards in mind, companies can avoid expensive modifications at later stages.

- Broadened Market Reach: UL's global recognition paves the way for smoother international market entries.

- Continuous Professional Growth: Staying updated with these evolving standards ensures you're always ahead in electronics design best practices.

As a part of your product strategy, obtaining and implementing recognized certifications such as UL can help you combine regulatory compliance and strategic vision. This, in turn, can enhance your product quality, market standing, and overall success. The following article discusses the intricacies of product certifications, best practices, and a refresher of everyday topics that product engineers should keep in mind at the beginning of their development process.

Common Misconceptions About Product Certification:

A common misconception is that UL tests every product themselves. Many envision a vast UL lab where endless rows of products undergo rigorous testing, day in and day out. UL does product testing directly, but they also authorize other test labs and facilities to test and certify products to the published UL standards. Intertek may be the largest and most widely recognized third-party certification laboratory. In some cases, even the manufacturer can test the product themselves using the UL standards. Of course, these third-party test facilities and manufacturers must be accredited by UL to ensure adherence to the published standards. UL will follow up regularly to make sure that they are testing the products and following proper guidelines.

Despite these varied testing approaches, one constant remains: UL's commitment to ensuring safety and compliance. Whether a product is assessed directly by UL, a third-party, or the manufacturer, UL continuously monitors and verifies the process. This is one of many reasons that UL certification is attractive to businesses. It is a universal symbol of testing and certification safety standards.

Basics Revisited: What is UL Certification and Why is it Important?

UL stands for Underwriter Laboratories, a third-party certification company that's been around for over a century. They certify products with a goal to make the world safer for both workers and consumers. Besides testing, they set industry standards to follow when designing new products.

In a nutshell, UL is a safety organization that sets industry-wide standards on new products. They continually check these products to ensure they're up to these standards. UL testing makes sure that wire sizes are correct, or devices can handle the current they claim to be able to. They also ensure that products are constructed correctly for the highest safety.

Strategic Importance: UL Certified vs. UL Listed products and components

A UL listed product ensures the longevity and safety of many products under normal wear and tear that comes with everyday use. Compared to UL Recognition, UL Listed status is primarily applied to individual components and materials which are utilized in product designs to streamline UL Compliance testing of the final product.

For some UL marks, the term "certification" is used to communicate that the organization has successfully tested the manufacturer's sample product against certain standards and specifications. The term "certification" does not imply "approval" or endorsement of the use of the component or product in all potential applications. UL certification is essentially an umbrella term in which UL listed and UL recognized fall.

In contrast, UL listing can refer only to stand-alone components and materials that have a specific function and were tested against UL's nationally recognized safety standards of a specific category of equipment.

UL Certification is the broad term for the various safety certifications offered by UL. Products have been tested to these standards and UL ensures, through on-site audits, that the manufacturer maintains the safety standard when building new products. Consumers value UL Certification to ensure their products are safe, and manufacturers must follow these industry standards when fabricating new products.

CE's Role: How Does CE Differ from UL Certifications?

In addition to UL, you might have seen other similar logo seals in other countries. For example, CE is a similar organization in the EU that sets standards for common electronics. CE stands for Comformité Européenne which is French for "European Conformity". CE is similar to UL, the main difference being the country in which it is manufactured and sold.

Much like UL, CE gives companies an advantage by being able to sell anywhere within the EU, while also being able to market the CE logo as a mark of safety in much the same way as the UL symbol. For these reasons, many companies opt to get CE certified to expand their sales marketing capacities into Europe and other countries.

There are several safety standards published under an "EN" or "IEC" designation that correspond to an equivalent or "harmonized" UL standard. By harmonizing the standards between UL and the EU there is a reduction of cost and complexity required by manufacturers to ensure their products meet all safety requirements.

Important design Considerations

When designing a piece of electronic equipment or an embedded control device consideration should be given by the designer to the inherent safety of the device during normal and, sometimes, abnormal operation.

Design considerations should revolve around any power inputs or outputs and any buttons, or switches or other parts that the user would contact.

What if there is a power supply component failure?

- Will the pc board overheat?

- Will it catch fire?

- Can it cause unsafe voltages and current to be exposed to the user?

What if the user or installer connects the main power input backwards or, the wrong power source?

- Will this destroy the unit?

- Will it cause breakers to trip in a power panel?

- Will it cause an injury to the installer or user?

These are all things that need to be considered and why testing to UL and IEC safety standards is not only a good idea, but it's also important to protect the end user.

Question: What are some of the things that are checked and what is the process that must be done to ensure your design is inherently safe?

Answer: A lot of that depends on the piece of equipment you're designing and, what its main function is and how it is installed and used.

Products are tested to determine inherent construction safety and safe operation. Safety is checked in the areas of protection against electric shock, heating, electric strength, provision for earthing, mechanical strength, endurance, and abnormal use, etc. If the device is exposed to the elements or mounted outdoors, is it weatherproof? Will the enclosure deteriorate due to ultra-violet light exposure?

There are different safety standards and test methods for different types or categories of products and equipment. Most embedded electronic systems fall into one of the following categories.

Information technology equipment

- IEC 60950 – standard for safety for information technology equipment. These can include all types of computers, printers, rack servers and networking equipment.

Audio/Video Information and, communication technology equipment

- IEC 62368 – standard for safety in audio equipment, video equipment and communication equipment including telephone switching equipment.

Electrical controls for heating/cooling devices, including the coffee maker in your home (heating device), your clothes dryer or even a large industrial HVAC system for a building or factory.

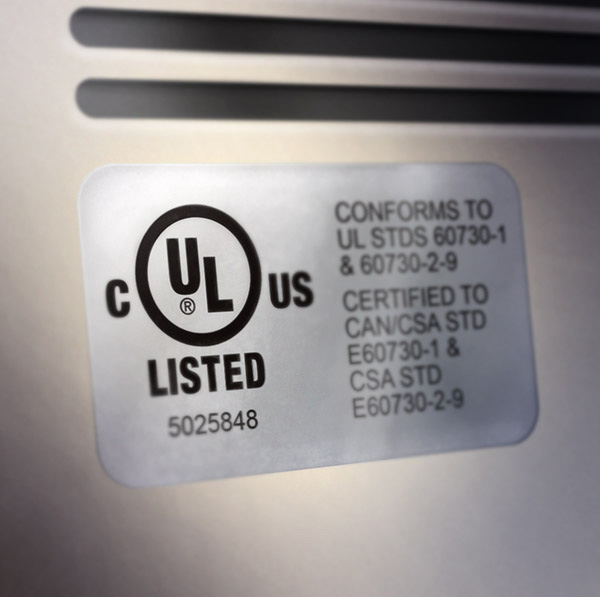

- IEC 60730 / UL 60730 – safety standard for automatic electrical temperature sensing controls for use in, on or in association with equipment, including electrical controls for heating, air-conditioning, and similar applications.

Industrial controls such as motor controls, PLCs, and factory automation controllers.

- IEC 60947 / UL 60947 - safety standard for Industrial controls such as motor controls, PLC and factory automation controllers.

Medical electrical equipment, laboratory electronic devices, and medical electrical systems.

- IEC 60601 – safety standard for the basic safety and essential performance of medical electrical equipment and medical electrical systems.

Electrical equipment for measurement, control, and laboratory use.

- IEC 61010 – safety standard for electrical equipment, used for measurements and control of equipment in a laboratory (indoor) environment.

Preparing for Safety Testing:

Typical things you will need to provide for Safety Testing.

- A written description of the product's installation and operation.

- A user manual or installation manual if available.

- At least (2) working samples of the product, in a representative enclosure.

- A sample and datasheet for the final material to be used for the enclosure.

- Keep in mind flammability ratings and UV protection if needed.

- Electrical schematic showing all electrical connections.

- Bill of Materials with manufacturer and manufacturer's part number

- Be sure to include any substitute parts you may plan to use.

- Gerber files for the PC Board and an assembly drawing of the PCB Assembly

- Intended use, location (indoors/outdoors), operating and storage temperature limits.

The schematic and bill of materials is checked for voltage and current levels of components are proper for the application and the specified temperature ratings. Ensuring proper fusing or protection circuits are applied. The level of scrutiny and safety protocols are driven by voltage and power levels used in a device. If it is less than 25V and under 5 watts of power, then the safety criteria are much less.

If voltages go above 300 volts, then more stringent safety protocols are applied, and designs are scrutinized for proper clearance and insulation from each other and from the end user.

The safety standards listed above are only a small sample. Automotive, off-highway and agriculture equipment for example, have a whole set of electrical, mechanical, and environmental standards that they must meet. This includes testing at temperature extremes and mechanical testing for shock and vibration. Shock and vibration issues can be minimized by proper component selection and good mechanical mounting techniques.

Product certifications are crucial in electronics engineering. Compliance with these protocols can be a regulatory obligation and professional necessity. Certifications like those from Underwriter Laboratories (UL) impact design decisions, reliability, and market positioning. Adhering to recognized standards improves product quality, bolsters market reputation, and ensures long-term success. Engineers should equip themselves with this knowledge to ensure their innovations meet regulatory standards and stand out in the industry.

Let's Get Started

At DE Design Works, our goal is to deliver solutions that not only meet but exceed your expectations. With us, you can rest assured that your project is in the hands of the best in the industry.

Ready to embark on your next project? Contact us for more information or to request a quote. We look forward to working with you to turn your vision into a reality!

The Expertise of Two Decades

At DE Design Works, we are dedicated to being your reliable partner throughout the challenging UL or CE certification process. We understand the complexities of product testing, regulatory standards, and documentation intricacies, and we will be with you every step of the way to ensure a seamless certification journey. Our primary objective is to provide you with efficient and accurate assistance through the completion of the certification process. We utilize our extensive experience and expertise to anticipate potential issues and offer solutions quickly should they arise.

For 21 years, we have guided numerous customers, ranging from major corporations to small and medium companies, through the complex maze of certification requirements. We like to identify and address any potential challenges proactively. Our approach is not just about problem-solving; it is about ensuring everything is done correctly from the beginning. At the start of our collaboration, we engage with our clients during the 'discovery' phase to clearly understand their final certification needs. This proactive approach enables us to tailor electrical and mechanical designs to meet the requirements efficiently. We strive to help our clients with a smooth and hassle-free experience through the certification process.